Pumps and their classification:

Pump:

A pump is a device that moves liquids or gases, by mechanical action.

Operation of pump:

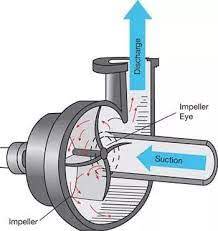

All pumps have an inlet, a casing, and an outlet. During operation liquid enters the pump through the inlet located here, this side of the pump is also called the suction side. The pressure of the liquid is lowest at this point. The purpose of the pump casing is to contain the liquid inside the pump during operation. The casing houses all of the pump's internal parts. The liquid leaves the pump through the outlet. This side of the pump is also called the discharge side. The pressure of the liquid is highest at this point.

Inside the pump, there is a component that physically moves the liquid through the pump. The type of component that's used determines the type of pump. Pumps can be grouped into two general categories, Positive Displacement Pumps, and Dynamic Pump.

A positive displacement pump makes a fluid move by trapping a fixed amount of the fluid and forcing or displacing that trapped volume into a discharge pipe or discharge system. Some positive displacement pumps use an expanding cavity on the suction side and a decreasing cavity on the discharge side.

Dynamic pumps impart velocity and pressure to the fluid as it moves past or through the pump impeller and, subsequently, convert some of that velocity into additional pressure. It is also called Kinetic pumps. These pumps operate by developing a high liquid velocity and converting the velocity to pressure in a diffusing flow passage.

Types of Positive Displacement Pump:

A positive displacement pump can be further classified according to the mechanism used to move the fluid.

There are three types:

1) Rotary-type positive displacement

2) Reciprocating-type positive displacement

3) Linear-type positive displacement

Rotary-Type Positive Displacement Pump:

The nature of a Rotary pump requires very close clearances between the rotating pump and the outer edge, making it rotate at a slow, steady speed. If rotary pumps are operated at high speeds, the fluids cause erosion, which eventually causes enlarged clearances that liquid can pass through, which reduces efficiency. Rotary positive displacement pumps fall into three main types:

Gear pumps:

Gear pumps are a simple type of rotary pump where the liquid is pushed between two gears.

Screw pumps:

Screw pumps are the shape of the internals of this pump is usually two screws turning against each other to pump the liquid.

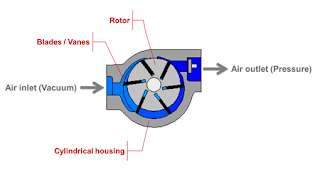

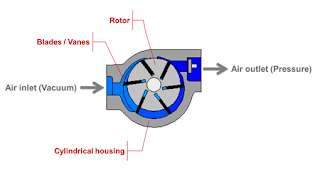

Rotary vane pumps:

These pumps are similar to scroll compressors; these have a cylindrical rotor encased in a similarly shaped housing. As the rotor orbits, the vanes trap fluid between the rotor and the casing, drawing the fluid through the pump.

Reciprocating-type positive displacement Pump:

Reciprocating pumps move the fluid using one or more oscillating pistons, plungers, or membranes (diaphragms), while valves restrict fluid motion to the desired direction. For suction to take place, the pump must first pull the plunger in an outward motion to decrease pressure in the chamber. Once the plunger pushes back, it will increase the pressure chamber and the inward pressure of the plunger will then open the discharge valve and release the fluid into the delivery pipe at a high velocity.

Typical reciprocating pumps are Plunger pumps:

A reciprocating plunger pushes the fluid through one or two open valves, closed by suction on the way back.

Diaphragm pumps:

Similar to plunger pumps, where the plunger pressurizes hydraulic oil which is used to flex a diaphragm in the pumping cylinder. Diaphragm valves are used to pump hazardous and toxic fluids.

Piston pumps:

Displacement pumps are usually simple devices for pumping small amounts of liquid or gel manually. The common hand soap dispenser is such a pump.

Dynamic pumps:

Dynamic pumps are one category of pumps under which there are several classes, two of which are: centrifugal pumps and special pumps.

Centrifugal Pumps:

A centrifugal pump is a rotating machine in which flow and pressure are generated dynamically. The energy changes occur under two main parts of the pump, the impeller, and the volute or casing. The function of the casing is to collect the liquid discharged by the impeller and to convert some of the kinetic (velocity) energy into pressure energy.

Centrifugal pumps are subdivided into several categories:

Axial Flow Pumps:

Axial Flow Pumps are high-flow, low-pressure pumps that lift fluid in a direction parallel to the impeller shaft.

Mixed Flow Pumps:

Mixed Flow Pumps are medium flow, medium pressure pumps which push fluid out away from the pump shaft at an angle greater than 90.

Radial Flow Pumps:

Radial Flow Pumps are high-pressure, low-flow pumps that accelerate fluid along with the impeller blades perpendicular to the shaft.

Special Pumps are subdivided into several categories:

There are also some special types of dynamic pumps which are defined by certain characteristics.

Cantilever Pumps:

Cantilever Pumps are centrifugal pumps with a long cantilever design used in sump pump applications.

Jet Pumps:

Jet Pumps are kinetic pumps with an ejector attached at the discharge outlet, utilizing the Ventura effect and motive fluid to generate pumping pressure.

Turbine Pumps:

Turbine Pumps are centrifugal pumps that use pressure in combination with a rotary mechanism with numerous small impellers and vanes to transfer energy to a fluid.